en

en

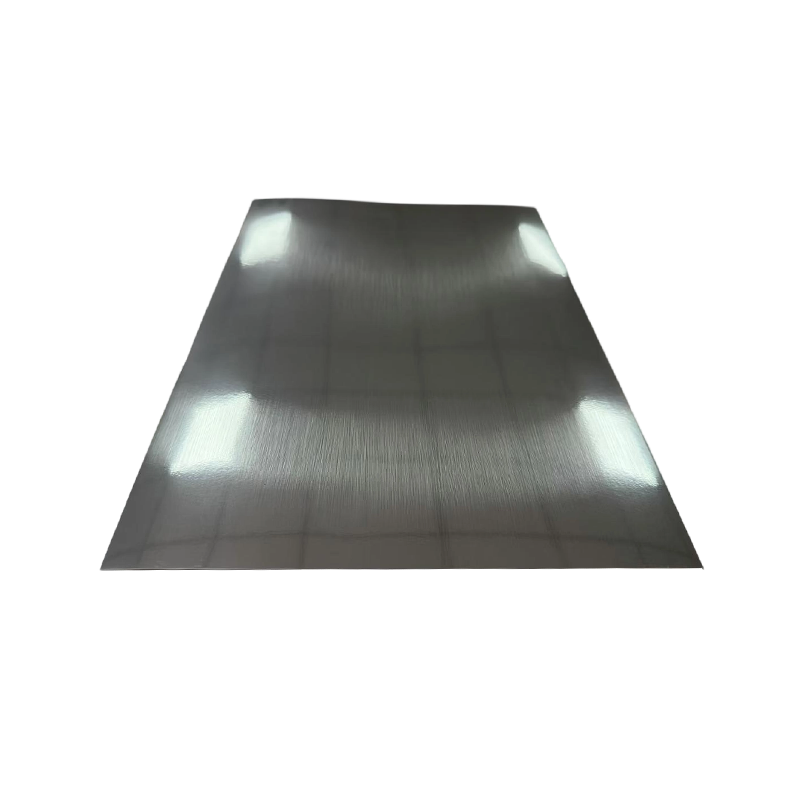

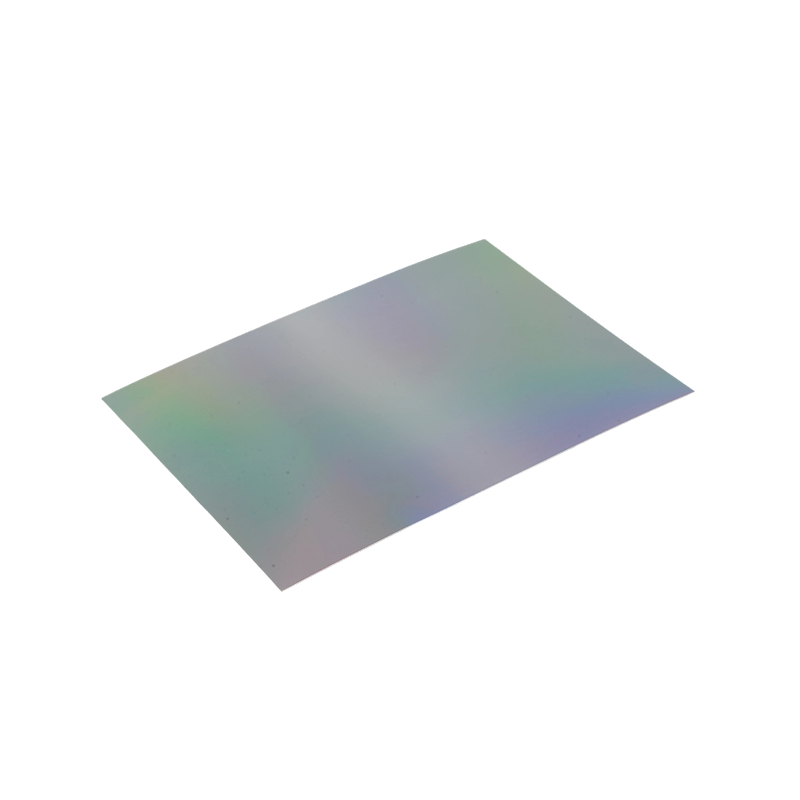

Brushed Silver Cardstock

Process: Substrate paper (coated paper or white cardboard, as well as other customized paper types) laminated with PET brushed silver film

Raw Materials: Substrate paper, PET brushed silver film, laminating adhesive, water-based varnish

Substrate Paper Basis Weight: Conventional coated paper: 128g, 157g, 200g; Conventional white cardboard: 210g, 250g, 300g, 325g, 350g, 400g

(Special basis weights available upon inquiry and pre-order) (Specifications can be customized)

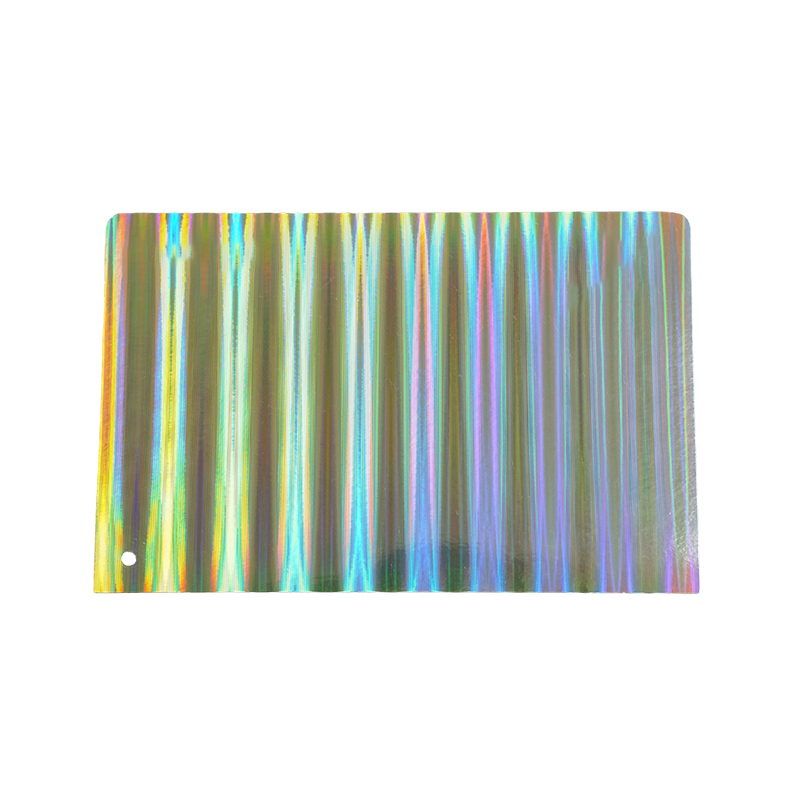

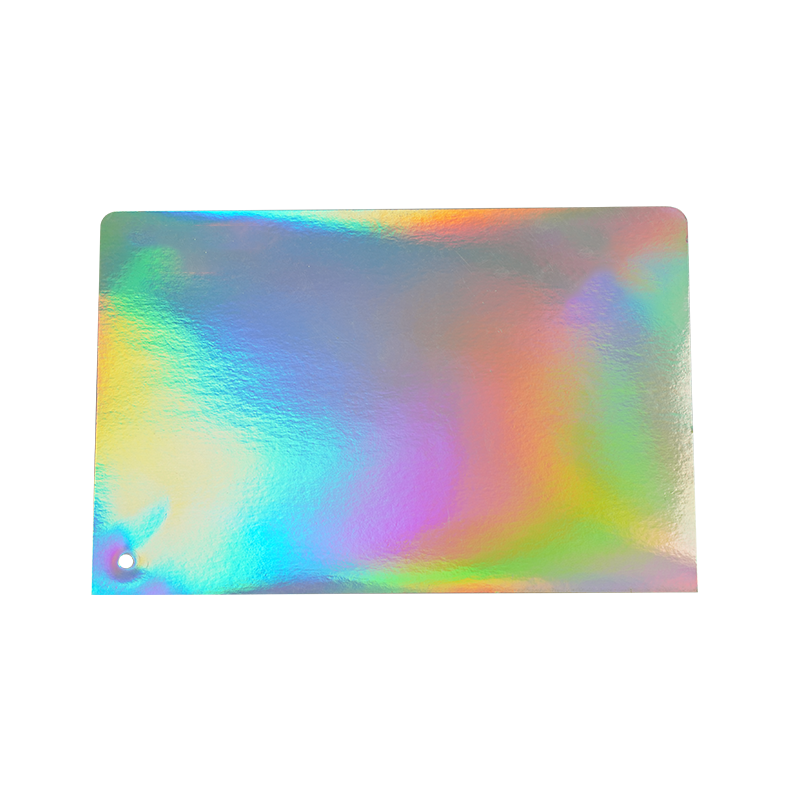

Brushed Silver Cardstock is a metallictextured paperboard with a fine, velvety brushed finish on its surface. Its base material consists of highgrammage paperboard, laminated with a special silver metallic coating and meticulously brushed to create a distinctive matte metallic texture with soft reflective highlights. This cardstock combines the easy workability of paper with the aesthetic appeal of metal, offering a smooth yet layered experience in both touch and vision. It is suitable for printing and production projects that demand highquality design texture, effectively enhancing the visual appeal and tactile memorability of the finished product.

Core Advantages

Unique Texture: The brushed texture effectively reduces the strong glare of fully glossy metallic cardstock, presenting a more understated and elegant visual appearance.

Processing Adaptability: While retaining its metallic sheen, it offers excellent compatibility with diecutting, creasing, embossing, debossing, and adhesive bonding.

Stability: The dense coating structure helps minimize fingerprint marks, and the base paper undergoes balanced humidity treatment for enhanced flatness.

Product Features

Surface Finish: Matte brushed texture with a smooth, delicate feel.

Base Weight: Available in various thicknesses, commonly ranging from 250gsm to 350gsm, with good stiffness.

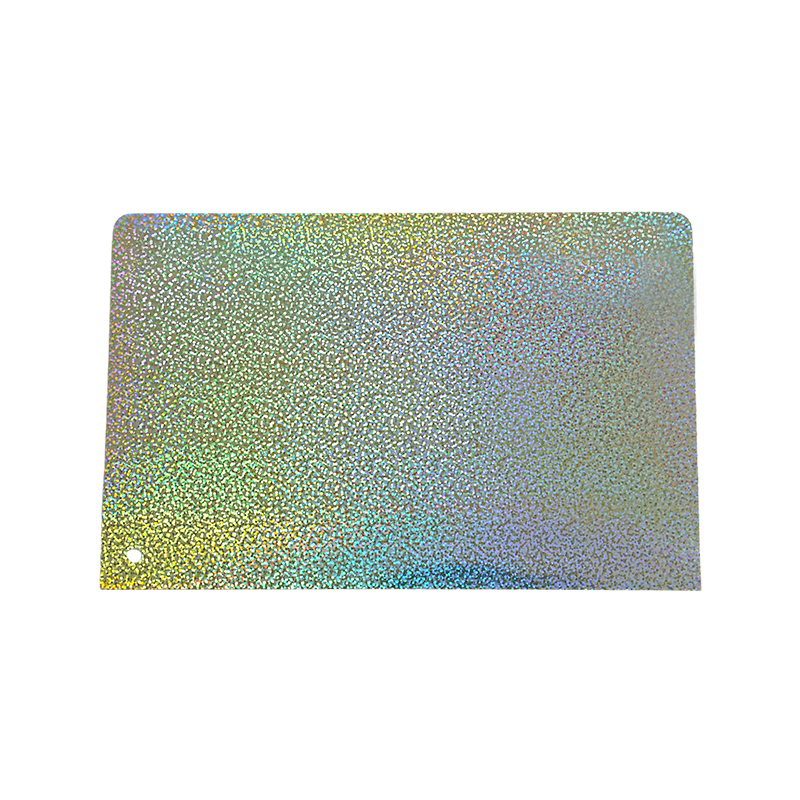

Printing Compatibility: Suitable for postprocessing techniques such as foil stamping (gold, silver, other colors), screen printing (UV ink), and laser engraving. Specialty oilbased offset printing can achieve clear results; sample testing is recommended.

Primary Color: Standard brushed silver, presenting a neutral silvergray tone.

Application Scenarios

HighEnd Printed Materials: Luxury hang tags, brand identity brochure covers, invitations, greeting cards, and certificates.

Packaging and Labels: Premium gift box wraps, wine labels, small electronics packaging, and durable tags.

Craft and Display: Handmade scrapbooks, photo album decorations, model making, instore display stands, and signage.

Storage and Usage Tips

It is recommended to store flat in an environment with a temperature of 18–25°C and relative humidity of 50% ±10% to prevent moisture absorption or curling.

Before printing or processing, allow the material to acclimate in the workshop environment for at least 24 hours.

For adhesive bonding, use hightack adhesives specifically designed for metalliccoated paper, and conduct a bond test on a corner first.

To clean surface dust, gently wipe with a soft, dry cloth.

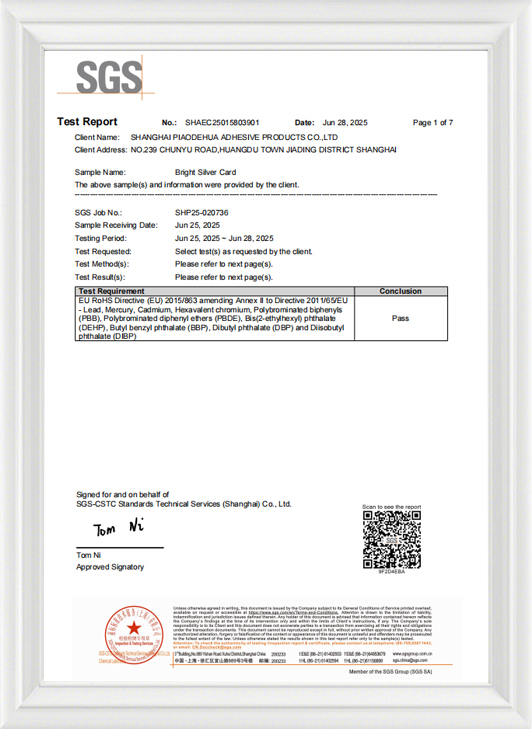

Shanghai Piaodehua Adhesive Products Co., Ltd. is a high-tech enterprise specializing in the R&D, production and sales of adhesive composite materials. Founded in 2002, the company is headquartered in Jiading District, Shanghai. Adjacent to Shanghai-Kunming Expressway, Zhajiasu Expressway, Shenjiahu Expressway, Shanghai Hongqiao International Airport and Shanghai Railway Station, it enjoys a superior geographical location and convenient transportation. To meet the needs of business expansion, the company established a branch factory in Taicang, Jiangsu Province in 2015. With over 20 years of in-depth cultivation in the gold and silver cardboard packaging field, the company has become one of the competitive composite material suppliers in the industry relying on its mature technical accumulation and large-scale production capacity.

-

0Established in

-

0㎡Factory Building Area

-

0+Professional Equipment

-

0+Employees

English

English